Our Technology

A distributed control system (DCS) is a computerized control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control.

This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localizing control functions near the process plant, with remote monitoring and supervision.

A PLC could be standalone or networked. DCS or Distributed Control System is a network of Highly Powerful PLCs and Data Server. PLC is usually used for controlling medium or large scale applications, whereas DCS is used for controlling entire plant.

Distributed control systems first emerged in large, high value, safety critical process industries, and were attractive because the DCS manufacturer would supply both the local control level and central supervisory equipment as an integrated package, thus reducing design integration risk. Today the functionality of SCADA and DCS systems are very similar, but DCS tends to be used on large continuous process plants where high reliability and security is important, and the control room is not geographically remote.

Providing Reliable Choices.

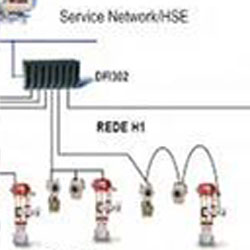

Profibus is a standard for fieldbus communication in automation technology, designed to monitor measuring equipment via a process control system in process automation applications.

Foundation Fieldbus is designed to address the needs of real-time process automation, and originally intended as a replacement for the 4-20mA standard. It is two-way communications system that serves as the base-level network in a plant or factory automation environment.

Let's discuss your project